Production Lab

At EverDear, we do all of our research and scientific experiments in-house. These research projects help us improve diamond quality & stability and enable us to personalise memorial diamonds in a shorter time frame and at a lower cost.

Our dedicated scientists and intellectual properties (IPs) make up the technical foundation of EverDear, which are our priceless assets that give us competitive advantages.

How do we make diamonds from ashes?

1 Ashes and Hair Refinement Process

Carbon Extraction

Cremation diamonds are made from carbon extracted from cremation ashes or hair. The carbon in these remains must be purified to an extremely high level.

At EverDear’s laboratory, we realize that this is one of the most crucial steps to create a cremation diamond from ashes or hair. It is at this stage of the transformation process, the color of the diamond is decided. The level to which the cremation diamond is processed defines the color. A cremation diamond naturally has a yellow hue due to the presence of nitrogen within hair and cremation ashes. After being purified of nitrogen, the cremation diamond takes on a bluish hue due to the presence of boron. Ashes that have been completely purified result in colorless diamonds and exude the aura of purity.

All ashes that EverDear receives are processed by heat in a vacuum environment, and are purified through various refinement processes depending on the desired color. The carbon content in everyone’s hair or ashes is different, so the results are unique for each.

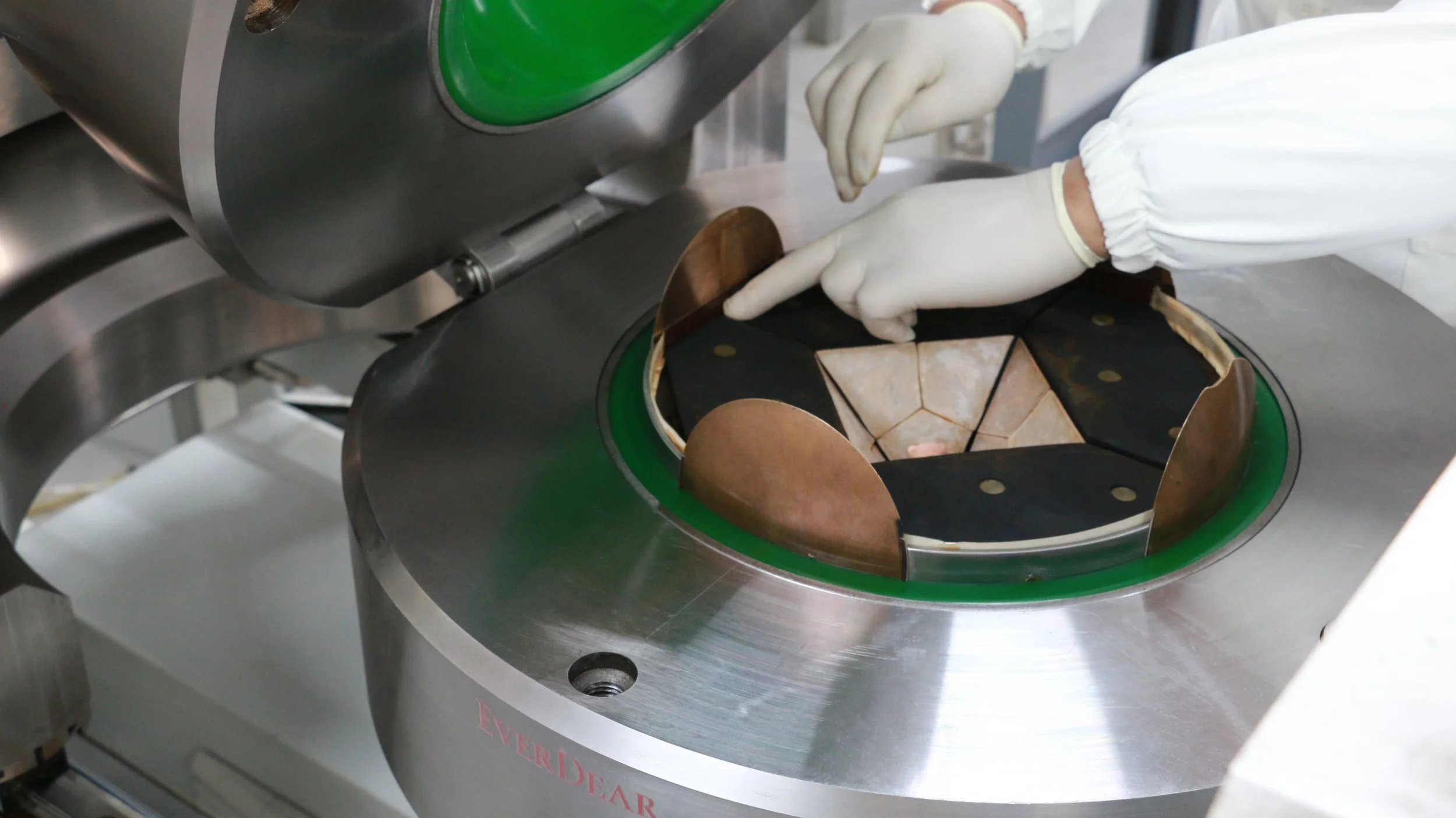

2 HPHT Growth Process

Diamond Crystallization

Natural diamonds are formed underground when the element carbon is subjected to both extreme amounts of pressure and excessively high temperatures. A High Pressure, High Temperature (HPHT) press is used to artificially simulate the natural environment in which carbon is transformed into a diamond. In this case, the carbon from ashes is transformed into a beautiful cremation diamond.

To create the cremation diamond, a tiny diamond seed is prepared and placed at the bottom of the press’ inner core cube. The interior of the press is heated to over 2000°F, melting a catalyst metal. The molten catalyst metal dissolves the high-purity, personal carbon source, which is then transported to the small diamond seed and crystalized. A cremation diamond is born and starts to grow like a shining star.

3 Diamond Polishing Process

Cutting & Polishing

Once a cremation diamond is created, it is raw and uncut, showing none of its true beauty and splendor, yet. To coax out its true potential, our expert artisans polish the cremation diamonds. First, the cremation diamond undergoes “crosswork,” in which the main facets are placed on the diamond. This ensures maximum weight, clarity, and the best angles for the specific diamond shape. Next, the diamond’s main facets are smoothed, also known as polishing. Last, the final facets are polished onto the diamond. The facets added are the stars, top and bottom halves also known as upper and lower girdle facets. This process has largely stayed the same for hundreds of years. However, our artisans use the latest tools to ensure precision work.

Research & Development

EverDear values research and development (R&D) and recognises the importance of intellectual property protection. The detailed technical process to turn ashes into diamonds and its applications are strictly safeguarded and maintained in absolute confidentiality.

Photos may be taken by our staff and provided for customers, but to ensure absolute confidentiality of our cutting-edge processes and technology, only business partners of EverDear are allowed to visit our laboratories and must adhere to our internal rules and regulations.

At EverDear, we are on the cutting edge of innovation in the cremation-diamond-from-ashes market. Through our technological innovation, we are able to deliver the highest quality diamonds from the ashes of the dearly departed at the most affordable cost.

In order to deliver on our commitment to quality and affordability, we here at EverDear™️ focus on five main points of quality: carbon refinement, diamond formation, cutting and polishing, the production site, and research and development.